We get your priorities!

Start a conversation with one of our engineers to discover a way forward.

Contact UsSenior team delivers solution to support the safety of gas handling in semiconductor plant.

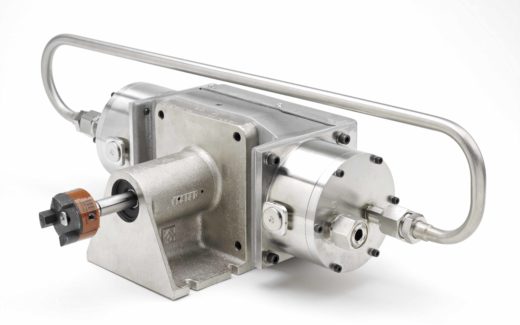

Moving highly toxic gases from bulk storage to the point-of-use is a perennial challenge for many semiconductor manufacturers. Unfortunately, most conventional pumps rely on seals that are subject to wear—potentially risking harmful leakage and human exposure.

We address the problem in two ways in order to achieve the highest levels of reliability and gas-handling safety: First, we employ metal bellows that incorporate seals made from Teflon™, Viton® or other metals that resist wear and are compatible with most gases. And secondly, we offer a double containment design, featuring a four-headed bellows, using a secondary bellows as a redundant leak-tight seal. Should a failure ever occur within the primary bellows, the secondary system prevents release of the toxic gas into the environment.

Absolute zero leakage to hermetic levels, components do not wear (no contaminants are generated. No loss of performance), leakage sensor monitors pump integrity, Teflon™, Viton® or all-metal seals for compatibility with most gases.

Start a conversation with one of our engineers to discover a way forward.

Contact Us