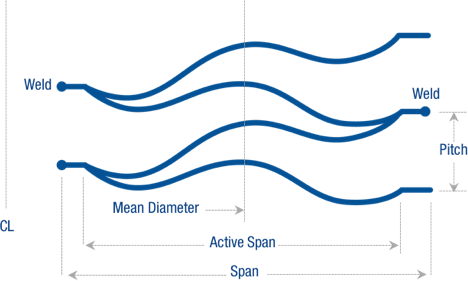

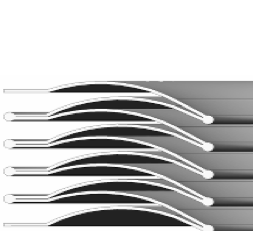

- GTAW & CO2 laser welding

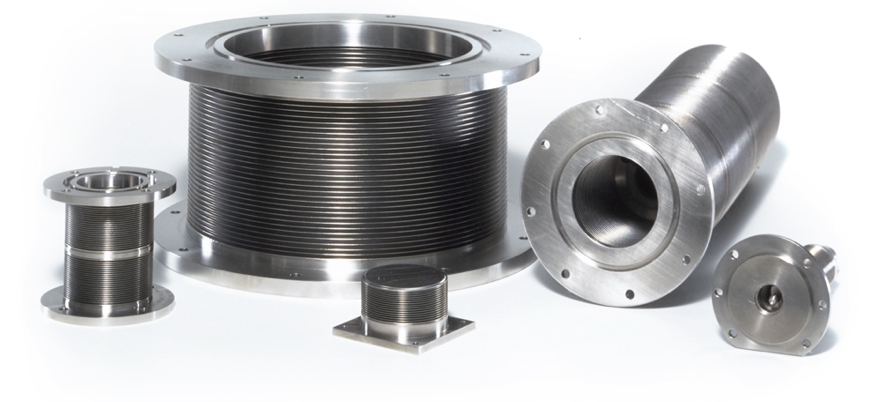

- Thickness (0.001 to 0.025 inches)

- Sizes, diameters (0.125 to 23 inches)

- Round and non-round

- Materials

- Stainless steels

- High nickel alloys

- Titanium

- Mass spectrometer leak tight

- 1 × 10-10 std cc/sec He capability (1 cc in 320 years)

- Zero leakage dynamic seal

2025 SMB Exhibitions

Learn More